Compressor Map

Xona Rotor's compressor maps are generated using the industry-leading CFD package ANSYS CFX, and validated with experimental data and testing.

Xona Rotor

This standard rotation turbo works great on its own or it can be paired with our XR6564SR X3C to create one E.C.H.O. set.

350-690 hp

Power Applications

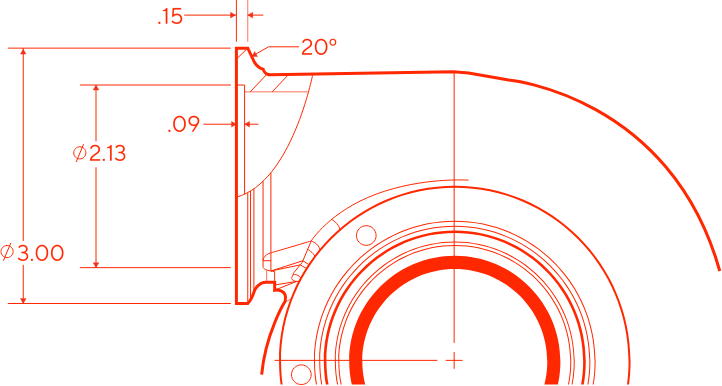

58/79 mm

Compressor Wheel

65 lb/min

Mass Flow

72/64 mm

Turbine Wheel

X3C

Compressor Housing

Xona Rotor has implemented innovative features in its XR line of performance turbochargers to enhance performance and durability.

The bearing housing itself is a fully-machined, high-strength stainless steel component with an extended water jacket. By fully surrounding the turbine seal ring land area, this advanced cooling feature combats heat soakback, preventing piston ring collapse for enhanced durability at high temperatures.